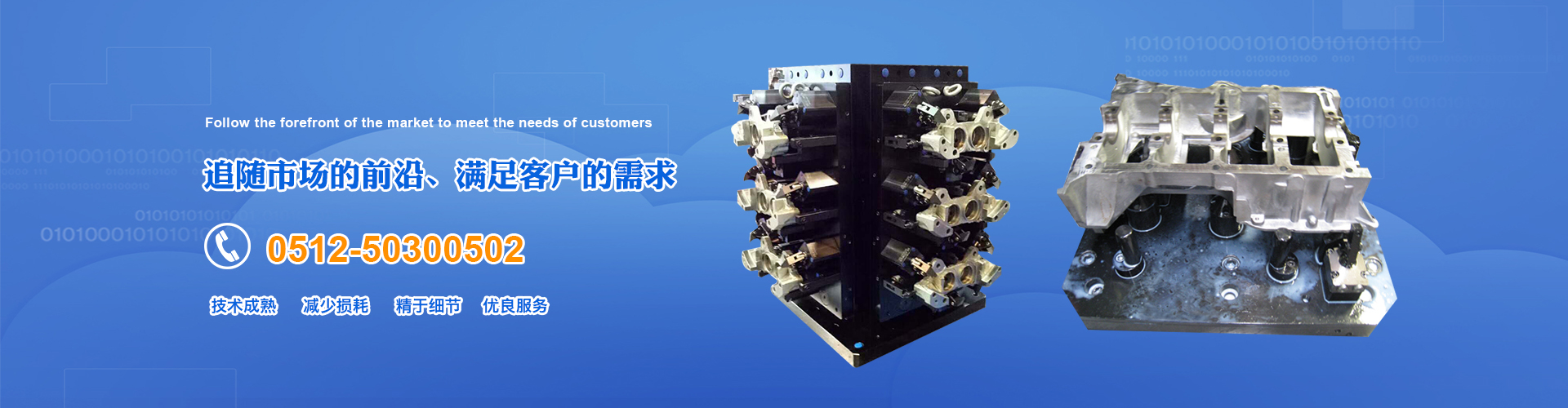

起重機(jī)力矩限制器

Crane moment limiter

臂架起重機(jī)的工作幅度是一個(gè)重要參數(shù)。起重量與工作幅度的乘積為起重力矩。當(dāng)起重量不變時(shí),工作幅度越大力矩就越大。當(dāng)起重力矩大于允許的極限力矩時(shí),會(huì)造成臂架折彎或折斷,甚至還會(huì)造成整機(jī)失穩(wěn)而傾翻。根據(jù)起重機(jī)械安全規(guī)程規(guī)定:履帶起重機(jī)、起重量≥16噸的汽車起重機(jī)和輪胎起重機(jī)、起重能力≥25噸的塔式起重機(jī)應(yīng)設(shè)力矩限制器。力矩限制器的綜合誤差不能大于10%,應(yīng)根據(jù)其性能和精確度進(jìn)行調(diào)整或標(biāo)定,當(dāng)載荷力矩達(dá)到額定起重力矩時(shí),能自動(dòng)切斷起升動(dòng)力源,并發(fā)出禁止性報(bào)警信號(hào)。常用的起重力矩限制器有機(jī)械式和電子式。

The working range of jib crane is an important parameter. The product of lifting weight and working range is lifting moment. When the lifting weight remains unchanged, the greater the working range, the greater the moment. When the lifting moment is greater than the allowable limit moment, the boom will bend or break, and even cause the whole machine to lose stability and overturn. According to the safety regulations for cranes, moment limiters shall be installed for crawler cranes, truck cranes and tyre cranes with lifting capacity of more than 16 tons and tower cranes with lifting capacity of more than 25 tons. The comprehensive error of the moment limiter should not exceed 10%. It should be adjusted or calibrated according to its performance and accuracy. When the load moment reaches the rated starting gravity moment, it can automatically cut off the lifting power source and send a forbidden alarm signal. The commonly used lifting moment limiters are mechanical and electronic.

動(dòng)壁式塔式起重機(jī)的超載保護(hù)裝置用電子式力矩限制器。它一般由力矩檢測(cè)器、工況選擇器和微型計(jì)算機(jī)等組成。其工作原理是:當(dāng)長(zhǎng)度、角度檢測(cè)器測(cè)出的臂長(zhǎng)、角度值及工作信息經(jīng)過(guò)數(shù)據(jù)采集電路進(jìn)入計(jì)算機(jī),計(jì)算出該工況的額定值,而力矩檢測(cè)器測(cè)出的信號(hào)經(jīng)過(guò)數(shù)據(jù)采集電路進(jìn)入計(jì)算機(jī),計(jì)算出實(shí)際值。將額定值與實(shí)際值進(jìn)行比較,當(dāng)實(shí)際值大于或等于額定值的90%時(shí),發(fā)出警告信號(hào);當(dāng)實(shí)際值達(dá)到額定值時(shí),發(fā)出禁止性報(bào)警信號(hào),并通過(guò)自動(dòng)停止回路,自動(dòng)停止起重機(jī)向危險(xiǎn)方向運(yùn)動(dòng),但允許起重機(jī)向安全方向運(yùn)動(dòng)。同時(shí),起重臂長(zhǎng)的長(zhǎng)度、角度、幅度、起重量等參數(shù)經(jīng)軟件程序中數(shù)字模型的計(jì)算,分別送到液晶顯示器顯示。

Electronic moment limiter is used for overload protection device of movable wall tower crane. It is generally composed of a moment detector, a condition selector and a microcomputer. Its working principle is that when the arm length, angle value and working information measured by the length and angle detector enter the computer through the data acquisition circuit, the rated value of the working condition is calculated, while the signal measured by the moment detector enters the computer through the data acquisition circuit and calculates the actual value. Comparing the rated value with the actual value, when the actual value is greater than or equal to 90% of the rated value, a warning signal is issued; when the actual value reaches the rated value, a prohibitive warning signal is issued, and the crane moves in dangerous direction is automatically stopped by automatically stopping the loop, but the crane is allowed to move in safe direction. At the same time, the length, angle, amplitude and lifting weight of the lifting arm are calculated by the digital model in the software program and sent to the LCD display separately.

小車變幅塔式起重機(jī)的超載保護(hù)裝置,一般使用起重量限制器和起重力矩限制器來(lái)共同實(shí)施超載保護(hù)。起重量限制器是一個(gè)測(cè)力環(huán),與起重鋼絲繩導(dǎo)向滑輪剛性連接。測(cè)力環(huán)隨載荷變化產(chǎn)生變形,并按設(shè)計(jì)程序通過(guò)不同的控制觸電。起重量限制器有兩個(gè)作用,一是當(dāng)載荷達(dá)到某個(gè)值時(shí),限制檔位提升速度;二是當(dāng)載荷達(dá)到最大值時(shí),切斷起升回路電源。設(shè)計(jì)原則是使起重機(jī)輕載高速,重載低速,超載停止。

The overload protection device of trolley luffing tower crane generally uses lifting weight limiter and lifting moment limiter to jointly implement overload protection. Lifting limiter is a force measuring ring which is rigidly connected with the guide pulley of the lifting wire rope. The force measuring ring deforms with the change of load, and electric shock is controlled by different design procedures. The lifting weight limiter has two functions: one is to limit the gear lifting speed when the load reaches a certain value; the other is to cut off the power supply of the lifting circuit when the load reaches the maximum value. The design principle is to make the crane light load high speed, heavy load low speed, overload stop.

橋架型起重機(jī)起重量限制器

Lifting Limiter of Bridge Crane

起重量限制器是起重機(jī)超載保護(hù)裝置中最重要的部分,它主要用于橋架型起重機(jī),一般由載荷傳感器和二次儀表部分組成。傳感器使用應(yīng)變式或壓磁式傳感器。二次儀表由放大、比較、顯示、控制等單元組成。現(xiàn)在,由于科技的發(fā)展使許多產(chǎn)品具有愈來(lái)愈多的附加功能,如大屏幕顯示、計(jì)算打印等。

Lifting Limiter is the most important part of crane overload protection device. It is mainly used for bridge crane. It is generally composed of load sensor and secondary instrument. Sensors use strain or piezomagnetic sensors. The secondary instrument consists of amplification, comparison, display and control units. Nowadays, with the development of science and technology, many products have more and more additional functions, such as large screen display, computing and printing.

起重量限制器的安裝形式有四種:吊鉤式、鋼絲繩式、軸承式和定滑輪式。

There are four installation forms of lifting limiter: hook type, wire rope type, bearing type and fixed pulley type.

1、吊鉤式安裝形式。吊鉤式安裝形式的產(chǎn)品結(jié)構(gòu),有直接顯示式、調(diào)頻發(fā)射式和分離式三種。直接顯示式用于鎳鎘電池做電源,將吊鉤、傳感器、大屏幕顯示器做成一體,裝在起重機(jī)吊鉤上。調(diào)頻發(fā)射式也采用鎳鎘電池總電源,但沒(méi)有顯示部分,而是將傳感器信號(hào)經(jīng)調(diào)頻后送司機(jī)室,由二次儀表把信號(hào)還原在進(jìn)行控制與顯示。這兩種形式傳感器與二次儀表之間不用電纜相連,但價(jià)格較高。分離式則將傳感器信號(hào)經(jīng)電纜傳給二次儀表,經(jīng)處理后進(jìn)行控制與顯示。

1. Hook type installation. The product structure of hook type installation includes direct display type, FM transmitting type and separate type. The direct display type is used for power supply of nickel cadmium batteries. The hook, sensor and large screen display are integrated and mounted on the crane hook. FM transmitter also uses the total power supply of nickel-cadmium batteries, but does not display the part. Instead, the sensor signal is sent to the driver's cab through FM, and the signal is restored by the secondary instrument for control and display. There is no cable connection between the two types of sensors and secondary instruments, but the price is higher. Separate type transmits the sensor signal to the secondary instrument through the cable, which is controlled and displayed after processing.

2、鋼絲繩張力式。使用專用夾具,把傳感器安裝在起重鋼絲繩,經(jīng)過(guò)檢測(cè)鋼絲繩的張力來(lái)反映載荷。這種方式安裝方便,檢測(cè)精確度高。

2. Tension type of wire rope. Using special fixture, the sensor is installed in the lifting wire rope, and the load is reflected by detecting the tension of the wire rope. This method is easy to install and has high detection accuracy.

3、軸承座式。軸承座式安裝形式的傳感器采用雙剪切梁式或圓柱形,配以專用附件,組成一個(gè)軸承座,安裝在鋼絲繩卷筒非減速器一側(cè)。該形式裝置方便,易于維修、精確度較高。

3. Bearing seat type. Bearing seat type sensor adopts double shear beam type or cylindrical type, with special accessories to form a bearing seat, which is installed on the non-reducer side of wire rope drum. The device is convenient, easy to maintain and has high accuracy.

4、定滑輪式。定滑輪式有兩種具體安裝形式。一種是配置一套托板支架,將定滑輪軸略微抬起,式安裝在支架上的傳感器承受載荷;另一種是支配定滑輪軸,把傳感器壓進(jìn)軸的一端,安裝時(shí)用這一根軸換掉原定滑輪軸即可。

4. Fixed pulley type. The fixed pulley type has two specific installation forms. One is to install a set of bracket bracket, which lifts the fixed pulley shaft slightly and loads the sensor mounted on the bracket; the other is to control the fixed pulley shaft and press the sensor into one end of the shaft, and replace the original pulley shaft with this shaft when installing.